Nickel Sulfate

Nickel Sulfate Specification

- Poisonous

- Yes (harmful if ingested or inhaled)

- Ph Level

- 4.0-4.5 (1% solution)

- Smell

- Odorless

- Structural Formula

- NiSO47H2O

- Water Insoluble

- <0.01%

- Flash Point

- Non-flammable

- Melting Point

- >100C (dehydrates and decomposes before melting)

- Boiling point

- Not applicable (decomposes before boiling)

- HS Code

- 28332500

- Storage

- Store in a cool, dry, well-ventilated area, away from incompatible substances

- Place of Origin

- India

- Molecular Weight

- 262.85 g/mol (heptahydrate)

- Solubility

- Freely soluble in water

- Application

- Electroplating, catalyst manufacture, laboratory reagent

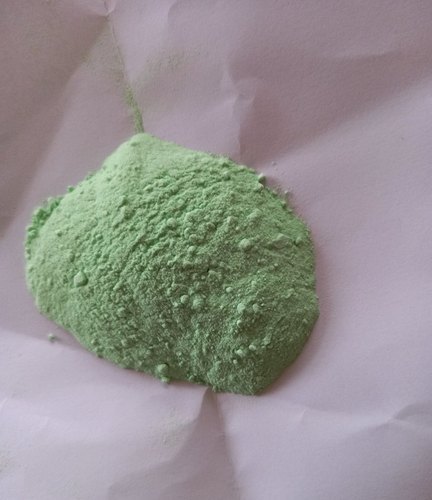

- Color

- Green

- Purity

- 98% Min

- Hazard Class

- 6.1 (Toxic substances)

- CAS Number

- 10101-97-0

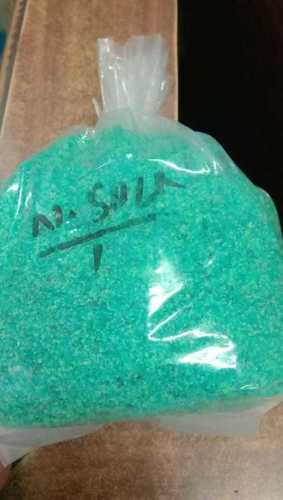

- Appearance

- Bluish-green or emerald green monoclinic crystals

- Density

- 2.07 g/cm³ (hexahydrate)

- Physical State

- Crystalline solid

- EC Number

- 232-104-9

- Shelf Life

- 2 years under recommended storage

- pH of 5% Solution

- ~4.5

- Crystal Structure

- Monoclinic (hexahydrate form)

- Packaging Type

- 25 kg bag/drum or as required

- Refractive Index

- 1.510 (hexahydrate)

Nickel Sulfate Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 1 Days

About Nickel Sulfate

Used as a common source of nickel sulphate in the laboratory and in electroplating baths, our nickel sulphate is a chemical compound available in blue colored salt. Some of the special features of Nickel Sulfate comprises of the following:

Features:

- Efficient working

- Definite composition

- Used in electroplating baths

Uses : Used as a common source of Nickel Sulphate in the laboratory and in electroplating baths, our nickel sulphate is a chemical compound available in blue colored salt.

Specifications:

- Molecular Formula: NISO46H2O

- Mol. Wt: 262.85

- Description: Emerald Green Crystal of Crystalline Powder

- Solution (10% W/v 5N HCL): Almost Clear

- Assay (as Ni) % w/w: 21-23 Maximum Limits of Impurities

- Chloride (Cl) % w/w: 0.01

- Sulphate (SO4) % w/w: 0.5

- Iron (Fe) % w/w: 0.02

- Nitrate (NO3) % w/w: 0.001

Other Information

- Minimum Order Quantity: 5 Kilogram(s)

Versatile Industrial Applications

Nickel Sulfate is preferred in electroplating industries for delivering smooth, corrosion-resistant nickel coatings. Its also essential in manufacturing catalysts and for use as a laboratory reagent. Its controlled purity and excellent solubility ensure consistent performance and reliable outcomes in various industrial processes.

Consistent Physical Properties

With a density of 2.07 g/cm (hexahydrate) and a distinct green monoclinic crystalline appearance, Nickel Sulfate stands out for its stability. The refractive index of 1.510 and pH stability (~4.0-4.5 in solution) make it suitable for precise chemical formulations and industrial uses.

Safe Handling and Storage

Given its toxic classification (Hazard Class 6.1), Nickel Sulfate must be handled with care. Store in tightly sealed containers in cool, dry, and ventilated conditions away from incompatible substances. The product does not burn but should still be handled using appropriate personal protective equipment and standard safety protocols.

FAQs of Nickel Sulfate:

Q: How should Nickel Sulfate be stored to ensure its maximum shelf life?

A: Nickel Sulfate should be kept in a cool, dry, and well-ventilated location, sealed tightly in its original packaging or compatible containers. Proper storage prevents moisture absorption, contamination, and decomposition, ensuring a shelf life of up to two years.Q: What processes commonly utilize Nickel Sulfate and why is it preferred?

A: Electroplating is the primary process utilizing Nickel Sulfate due to its high purity and excellent solubility. These qualities ensure uniform nickel deposition, resulting in corrosion-resistant finishes. It is also used in catalyst manufacture and as a laboratory reagent for reliable chemical reactions.Q: When is Nickel Sulfate considered hazardous and what precautions are necessary during use?

A: Nickel Sulfate is classified as a toxic substance (Hazard Class 6.1) and is harmful if ingested or inhaled. Workers should wear protective gloves, masks, and safety goggles. Adequate ventilation and spill containment measures are recommended during handling and processing.Q: Where is Nickel Sulfate supplied from and in what packaging options?

A: Nickel Sulfate is manufactured and exported from India. It is typically supplied in 25 kg bags or drums, but custom packaging options are available as required by the customer or application needs.Q: What are the physical characteristics of Nickel Sulfate?

A: Nickel Sulfate appears as bluish-green to emerald green monoclinic crystals, is odorless, and has a density of 2.07 g/cm (hexahydrate). It is non-flammable, freely soluble in water, and stable under standard storage conditions.Q: Can Nickel Sulfate be used in aqueous processes and what benefit does its solubility offer?

A: Yes, Nickel Sulfate is highly soluble in water with water-insoluble content below 0.01%. This excellent solubility facilitates fast and uniform mixing in aqueous processes such as electroplating baths, maximizing efficiency and performance.Q: What is the benefit of using Nickel Sulfate with a minimum 98% purity in industrial applications?

A: High purity Nickel Sulfate ensures minimal contamination and unwanted reaction byproducts. This results in consistent, high-quality outcomes in sensitive applications like electroplating and catalyst production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nickle Salts Category

NICKEL FLUORIDE

Minimum Order Quantity : 10 Kilograms

Structural Formula : NiF2

Water Insoluble : No

Smell : Other, Odorless

Application : Other, Laboratory reagent, catalysts, chemical synthesis

Poisonous : Other, Yes, toxic

Bright Nickel Salt

Minimum Order Quantity : 100 Kilograms

Structural Formula : NiSO46H2O

Water Insoluble : <0.05%

Smell : Other, Odorless

Application : Other, Electroplating, Surface finishing

Poisonous : Other, Toxic

Nickel Nitrate Hexahydrate

Minimum Order Quantity : 100 Kilograms

Structural Formula : Ni(NO3)26H2O

Water Insoluble : Negligible

Smell : Other, Odorless

Application : Other, Electroplating, catalyst, laboratory reagent, ceramics, metal surface treatment

Poisonous : Other, Yes (toxic if ingested or inhaled)

Nickel Carbonate

Minimum Order Quantity : 100 Kilograms

Structural Formula : NiCO3

Water Insoluble : Yes

Smell : Other, Odorless

Application : Other, Electroplating, catalyst, ceramics, pigments, nickel salt production

Poisonous : YES

Send Inquiry

Send Inquiry