Bright Nickel Salt

Bright Nickel Salt Specification

- Poisonous

- Toxic

- HS Code

- 28332990

- Storage

- Store in a cool, dry place, away from direct sunlight

- Flash Point

- Non flammable

- Structural Formula

- NiSO46H2O

- Place of Origin

- India

- Ph Level

- Approx. 4 5

- Boiling point

- NA (decomposes before boiling)

- Molecular Weight

- 262.85 g/mol

- Water Insoluble

- <0.05%

- Solubility

- Highly soluble in water

- Melting Point

- > 400C (decomposes)

- Smell

- Odorless

- Application

- Electroplating, Surface finishing

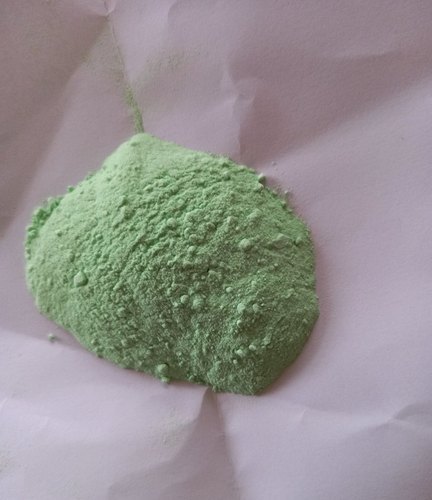

- Color

- White crystalline powder

- Shelf Life

- 24 months sealed

- Moisture

- 1.5% max

- Nickel Content

- 22-23%

- Hazard Class

- 6.1 (Toxic substances)

- Shelf Stability

- Stable under recommended storage conditions

- Purity

- 99% (minimum)

- pH (5% Solution)

- Around 4.3

- Compatibility

- Compatible with standard bright nickel electroplating systems

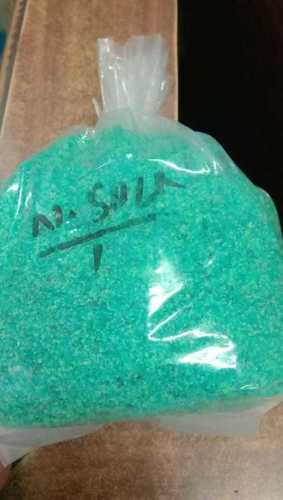

- Appearance

- Free flowing crystalline powder

- Handling

- Use protective gloves and goggles to avoid direct contact

- CAS Number

- 10101-97-0

- Packing Type

- HDPE bags with inner liner, 25 kg net

Bright Nickel Salt Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Bright Nickel Salt

ANALYSIS RESULT

The Bright nickel salt is suited for the levelers, brighteners and other compounds. This is used during nickel electroplating as well as electroforming. It is a highly balanced bright nickel system that can produce bright deposits of high ductility and good levelling. This is also apt for gold plating. Bright nicker salt is an essential part of duplex nickel system. This is needed to improve the physical properties such as heat resistance, wear resistance and corrosion resistance. This serves the dual role of making a bright decorative coating. It is useful for imparting boosted corrosion resistance as well as other functional properties.

| TESTS | STANDARD | FOUND |

| Appearance | POWDER | POWDER |

| BORIC ACID | 10.00 - 14.00 | 11.97 |

| Chloride | 4.00 - 5.50 | 5.00 |

| COLOUR | GREEN | GREEN |

| NICKEL SULPHATE | 70.00 80.00 | 73.98 |

| PERFORMANCE | SHOULD PASS | PASSES |

Superior Purity & Stability

Bright Nickel Salt boasts a 99% minimum purity and is carefully processed for high nickel content and exceptional stability. Its crystalline form assures efficient dissolution, while a shelf life of up to 24 months in sealed packaging makes it suitable for long-term storage in industrial environments.

Optimized for Electroplating

Designed specifically for electroplating and surface finishing, this product ensures uniform coverage and a brilliant finish. Its compatibility with standard bright nickel electroplating systems makes it a preferred choice for manufacturers seeking consistent results.

Secure Packaging & Safe Handling

Packed in robust HDPE bags with inner liners, Bright Nickel Salt is protected from moisture and contamination. Safety is paramount; users are advised to handle it with gloves and goggles due to its toxic nature, and always store it in a cool, dry place away from sunlight.

FAQs of Bright Nickel Salt:

Q: How is Bright Nickel Salt used in electroplating processes?

A: Bright Nickel Salt is dissolved in water to prepare the nickel electrolyte solution for electroplating. Its high solubility and purity help produce smooth, bright nickel coatings on metals during the electroplating process.Q: What safety precautions should be taken while handling Bright Nickel Salt?

A: Since it is classified under hazard class 6.1 (toxic substances), handlers should wear protective gloves and goggles and avoid direct contact with the product. Ensure good ventilation and store it away from direct sunlight in a cool, dry area.Q: Where should Bright Nickel Salt be stored to maintain shelf life and stability?

A: Store Bright Nickel Salt in sealed HDPE bags with inner liners, in a cool, dry place away from direct sunlight. Following these storage guidelines helps preserve its stability and ensures a shelf life of up to 24 months.Q: What are the benefits of using Bright Nickel Salt in industrial applications?

A: Its high purity and compatibility with standard electroplating systems ensure reliable, bright, and uniform finishes. The products stability, long shelf life, and secure packaging also make it convenient for manufacturers and exporters.Q: When is Bright Nickel Salt suitable for use in surface finishing?

A: Bright Nickel Salt is ideal for use whenever a bright, corrosion-resistant nickel finish is requiredcommonly in automotive, electronics, and decorative industries. Its stable properties allow continuous use over the recommended shelf life without loss of quality.Q: What is the process for preparing Bright Nickel Salt solutions?

A: To prepare an electroplating solution, dissolve Bright Nickel Salt in water, typically at a pH of around 4.3. Make sure the mixture is well dissolved for optimum electroplating results.Q: Is Bright Nickel Salt compatible with all electroplating systems?

A: Yes, Bright Nickel Salt is compatible with standard bright nickel electroplating systems due to its chemical composition and high solubility, making it versatile across various industrial setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nickle Salts Category

NICKEL FLUORIDE

Minimum Order Quantity : 10 Kilograms

Solubility : Soluble in water

Melting Point : > 850C

Smell : Other, Odorless

Application : Other, Laboratory reagent, catalysts, chemical synthesis

Storage : Other, Store in tightly closed containers under dry conditions

Nickel Nitrate Hexahydrate

Minimum Order Quantity : 100 Kilograms

Solubility : Highly soluble in water

Melting Point : 56C

Smell : Other, Odorless

Application : Other, Electroplating, catalyst, laboratory reagent, ceramics, metal surface treatment

Storage : Other, Store in tightly closed containers, in a cool, dry, wellventilated area away from heat and incompatible materials

Nickel Sulfate

Minimum Order Quantity : 100 Kilograms

Solubility : Freely soluble in water

Melting Point : >100C (dehydrates and decomposes before melting)

Smell : Other, Odorless

Application : Other, Electroplating, catalyst manufacture, laboratory reagent

Storage : Other, Store in a cool, dry, wellventilated area, away from incompatible substances

Nickel Carbonate

Minimum Order Quantity : 100 Kilograms

Solubility : Soluble in acids, insoluble in water

Melting Point : Decomposes before melting

Smell : Other, Odorless

Application : Other, Electroplating, catalyst, ceramics, pigments, nickel salt production

Storage : Other, Store in tightly closed containers, in a cool, dry and wellventilated area

Send Inquiry

Send Inquiry